By Teri KO4WFP

Glenn W4YES and I headed to Camden, SC the first week of April for some much needed rest and relaxation. Usually when I travel, I schedule a POTA activation or two. However, this trip I decided to try something new – getting on the air QRP at our Airbnb.

Camden is the oldest inland community in South Carolina. According to the town’s website, the earliest permanent settlers arrived in 1750. They experienced a crushing defeat during the Revolutionary War when the Patriots were defeated in the Battle of Camden. After the Civil War, the town “evolved into a tourist mecca for Northeners and Midwesterners seeking a warmer winter climate.” Those tourists brought money and an equine culture developed around racing and polo.

Our first day in Camden, we visited the Revolutionary War Museum. Though small in size, the museum’s exhibits are of excellent quality. They do a great job explaining who lived in the area, the quandary they faced as to whether to be a Loyalist or Patriot (it wasn’t as easy a choice as it might appear), and battles fought there.

Our second day, we explored the National Steeplechase Museum. This museum explores the history of steeplechasing and the personalities involved – owners, trainers, jockeys as well as those who care for the horses. The museum pays homage to Marion duPont Scott who developed the Springdale Race Course where the museum is located. This race course hosts two prominent annual competitions – the Carolina Cup and the Colonial Cup.

We also spent some time driving through and walking in the historic neighborhoods of the city. The weather was gorgeous! Everywhere we looked, there were flowers – azaleas, wisteria, viburnum, and dogwoods (including the pink variety we do not see in Savannah).

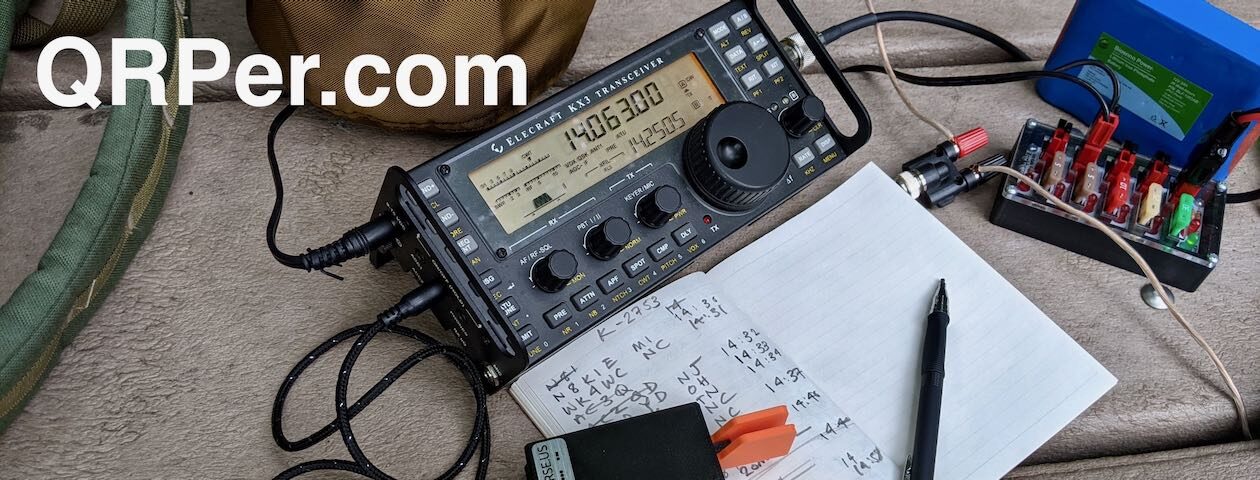

After exploring the area, it was time to explore the airwaves QRP at our Airbnb. To do this, I brought Craig, my KX2, and a home-brew linked dipole antenna. This is an antenna I built three years ago, when I first got into ham radio. At that time, I had no home station but wanted to get on the air portable for POTA. Despite knowing almost nothing about antennas, I built a usable dipole that became my main POTA antenna for quite a while.

Why did I bring this antenna to Camden? I have the opportunity this month to try the CFT1, a QRP transceiver, by Jonathan KM4CFT. Because the rig does not have an internal antenna tuner, I am reacquainting myself with the subject of resonance and why it matters in antennas.

I set up a home-brew linked dipole Wednesday evening under some trees in a space between the Airbnb and a small lake on the property. The antenna was roughly 20 feet in the air.

My RigExpert Stick analyzer gave me 2.1 at 7.040 –

Thinking I could do better, I moved the antenna (a real pain to do with a dipole) to a different tree with a limb 30 feet high. (Frankly, Glenn and I were amazed I could snag that limb.) This setup generated better a SWR reading – 1.61 at 7.040 MHz.

Now the true test – how well would I be heard?

On Wednesday evenings, I check into the OMIK CW net. OMIK is a ham radio club founded in 1952 by “Black amateur radio operators from the states of Ohio, Michigan, Indiana, and Kentucky to deal with discrimination” at that time. Though the club membership today is primarily African-American, others like myself are welcome.

CW nets are a great place to get on-the-air experience with morse code. It was my code buddy Caryn KD2GUT who first introduced me to the OMIK net. I found those who participate in this CW net to be welcoming and accepting of CW operators of all levels of proficiency. Over the past several years, the ops in this net have watched my skills grow and become friends.

Dennis NT4U and Steve W0SJS split net control station (NCS) duties. This evening, it was Dennis’ turn as NCS. As he is located in northern Georgia, I figured he would hear my QRP signal. He did and checked me into the net with a RST of 589. The icing on the cake was that I heard a station he was unable to hear – Charles AI4OT in Virginia – due to the S9 noise at Dennis’ location this evening. I notified Dennis of Charles’ check in so he was added to the check-in list for that evening. Way to go homebrew linked dipole and Craig!

The next day, Glenn did some exploring and found a better location on the property – a hill behind the Airbnb and some sheds. Several large oaks in this relatively open area offered prime limbs to snag with an arbor line. I installed the antenna on a limb roughly 25 feet up in the air.

Before attempting to check into another net, I spotted myself on QSO Finder, a new website and spotting tool by Mike N4FFF and Becky N4BKY of Ham Radio Duo. I had three exchanges, one each with Joel KE8WIC, Tom NG4S, and James KJ3D.

On Thursday evenings I check into the Sideswiper Net, a wonderful group of guys who meet on 40 or 30 meters (depending on propagation). Most of those who check in use a sideswiper (also known as a cootie) key but, like the OMIK CW net, they are welcoming of anyone who wants to participate no matter the level of proficiency or key. I’ve asked lots of questions of the members and appreciate their patience schooling me about CW nets.

The NCS this evening was Darrell AA7FV who is located in Arizona. The noise on 40 meters was rough but Darrel did copy me with a RST of 349. Two other stations – Bill WA4FAT in Alabama and Steve W1SFR – also copied me at 559 on this band.

When the net moved to 30 meters, my signal was worse. However, I expected that, as by this time it was dark and I didn’t want to mess with lowering the antenna to disconnect the link between the 40 and 30 meter wires. Darrel in Arizona could barely hear me (he gave me a RST of 129) but Bill could still copy me and acted as relay between our signals. I was thrilled that I had now checked into both nets QRP this week!

Even better, after the Sideswiper net, my code buddy Caryn KD2GUT and I were able to have our weekly code buddy QSO. We managed a 20 minute QSO on 40 meters before being swallowed up by noise and QRN on her end. Caryn is located on Long Island, NY. The previous night in the OMIK net, my signal was a 229 at her QTH. But tonight, we were both 599 and rocking it on the airwaves.

During the Sideswiper net and my code buddy QSO, I sat head copying in the dark under the moon and thought, “It doesn’t get any better than this, right?”

Before we left the Airbnb Friday morning, Glenn spied several pitchforks sitting by the sheds. We picked one up and decided to have some fun, with our version of the famous piece “American Gothic” by Grant Wood. I had a difficult time keeping a straight face (watch the video linked down below) but eventually we got the shot.

QRP has its limits; however, I was sufficiently impressed by my experience on this trip that I will travel with a rig from now on. I’d like a better antenna and have ordered an EFHW as that is probably my best bet for a resonant antenna. This hobby NEVER becomes boring because there is always something to learn.

I look forward to trying the CFT1 and my new EFHW antenna when it arrives. How will that turn out? Stay tuned…

Equipment Used

[Note: All Amazon, CW Morse, ABR, Chelegance, eBay, and Radioddity links are affiliate links that support QRPer.com at no cost to you.]

-

- Elecraft KX2

- CW Morse Single Paddle Cootie Key

- Homebrew Linked Dipole (20-30-40 meters)

- 50 ‘ length Tufteln RG-316 Coax

- Tufteln Knee Board

- Helinox Zero High-back Chair

- Weaver Throw Weight

- Marlow Excel Throw Line